By Channing Holland

Viscosity printing is a multi-colour printmaking technique that incorporates principles of relief and intaglio printing. The process uses the principle of viscosity to print multiple colours of ink from a single plate, rather than relying upon multiple plates for colour separation.

The process works on the principle that inks of high viscosity (sticky, tacky, dryer), rolled over a layer of an ink of a lower viscosity (thinner, runny, wetter) will be repelled. However, if the order is reversed, and ink with a lower, wetter viscosity is rolled over a layer of ink with higher, dryer viscosity it will be attracted to the first layer. Therefore, colours will either mix or juxtapose depending on their viscosity and the order they are rolled onto the plate. The distribution of the colours in the final print can additionally be manipulated by using hard or soft rollers, varying pressure on the rollers, and the depth and number of layers in the printing plate.

Two to three colours of ink are mixed, each of a different viscosity (thickness). This property is adjusted by the addition of solvents such as raw linseed oil, plate oil, or flash oil.

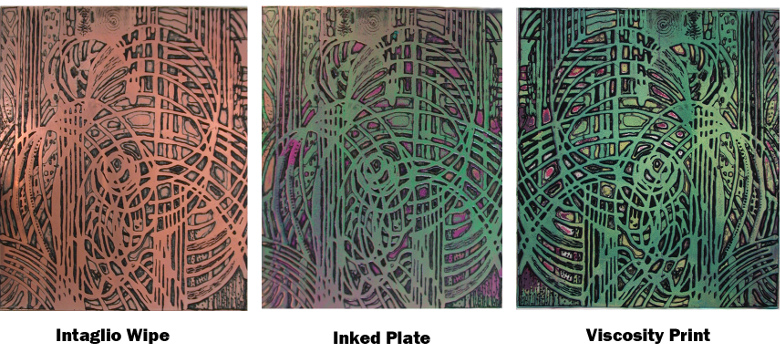

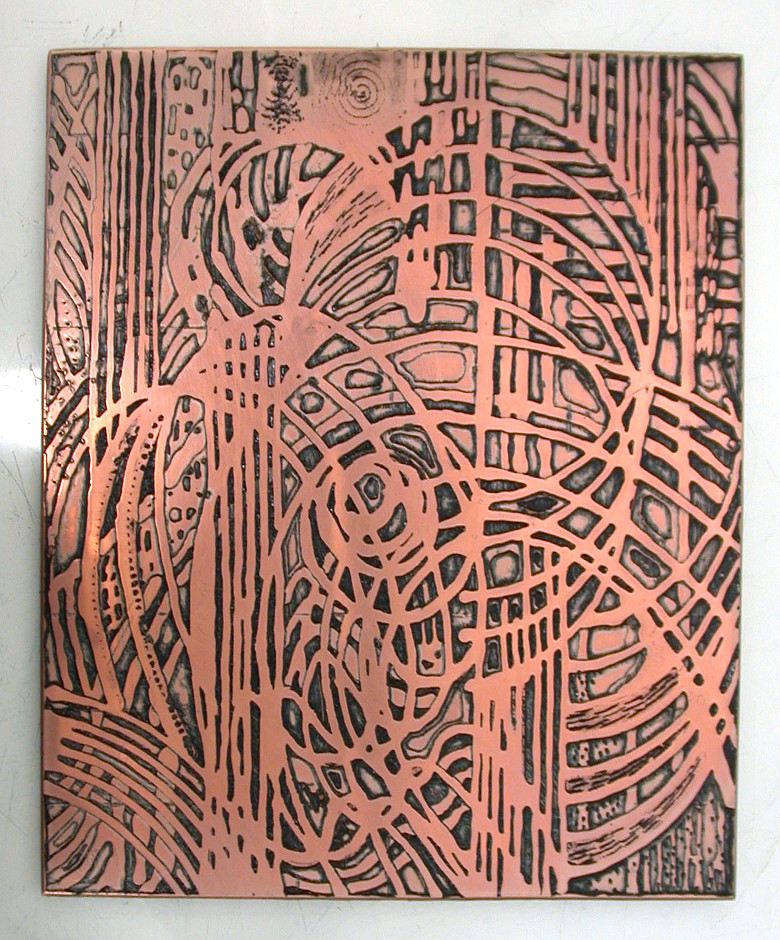

The artist produces images by creating lines or textures on a plate made of metal or cardboard. The metal plate method is called Etching and the image is produced by using acid to incise the image into the plate. The cardboard plate is called a Collagraph plate. It allows an image to be produced by cutting into the plate or gluing items onto the surface. The more layers and levels the better. The plate is then inked in several stages. Usually dark coloured ink of a high viscosity, is forced into the deepest recesses of the plate with a card or stiff brush and then wiped off the plate’s surface with a tarlatan (stiff gauze). This usually brings out details and is called an intaglio wipe.

The next colour, of a slightly thinner viscosity, is then applied to the surface of the plate with a rubber brayer (roller). The varying viscosities of the ink prevent them from mixing. A second colour, of even thinner viscosity, can also be applied at this point and even a third, thinner colour. The technique works best on plates that have been etched or built to several different depths.

A damp sheet of printing paper is then placed on the face-up plate and passed through a printing press, which prints all the colours simultaneously. This is an advantage, as registration of the plates in some other multi-colour printing processes can be difficult.

Channing Holland, Colour Notes, 1/1, etching

Metal etched plates or hand built collagraph plates are great for this method of printing. The results are not always entirely predictable but they are interesting, exciting and often spectacularly beautiful.

For a simple demonstration of this process see the following: https://thecuriousprintmaker.co.uk/viscosity-printing/

References:

Hayter, S. W. (1981). New Ways of Gravure. New York, NY: Watson-Guptill Publications.

Reddy, K. (1988). Intaglio simultaneous color printmaking: Significance of materials and processes. Albany, NY: State University of New York Press.